DESIGN OF

CORE AND FILTER IN EARTH AND ROCKFILL DAMS

1.0 DAMS AND THEIR DESIGN PHILOSOPHY

1.1 Role Played By Dams & Reservoirs

Dams have been

built across rivers by mankind right from the dawn of civilization for storing

the river flow during rainy season and releasing it during the remaining part

of year for either domestic use or for irrigation. Flood control has been

another important function of these dams. While releasing water from the

storages, hydroelectric energy is also generated. With the growth of population all these

functions of dams and storages have assumed great significance and hence every

civilization has tried to keep pace with the needs of the society for food,

energy, fibre and well being through this activity of water resources

development.

1.2 Inputs For Safe Design

Dams constitute

perhaps the largest and the most complex of structures being built by civil

engineers. Basic input of water is

dependent on nature, so also the river course, its history, its underlying

strata and its stability. Assessment of

the variability of these natural phenomenon and providing for it in the design

of a dam, has been an important challenge for the dam builders. The dams are built to last from 100 to 300

years depending upon merits of each case.

During their service life, they are designed to withstand all the

possible destabilizing forces with a certain factor of safety which has been an

indicator of a factor of ignorance or lack of knowledge of various response

processes of materials used in construction, the stresses caused, the stains

experienced and finally the failure mechanism.

ALSO READ: DESIGN PRINCIPLES OF EARTH DAM

ALSO READ: FOUNDATION TREATMENT FOR DAMS

1.3 Design Constants

The destabilizing

forces themselves are associated with a significant natural variability. Assessment of the range of these forces

likely to affect a dam stability during its lifetime and then ascribing a

design value for such forces has been and will continue to be a matter of study

and concern for the designers. Every

design or construction engineer cannot study these processes for every dam and

hence standards or codes of design and construction practice are laid down and

updated as information and knowledge grows

Assistance of scientists working in fields such as Hydrometeorology,

Geology, Geophysics, Geomorphology, Seismology in assessing the likely

parameters of these forces is taken, the information collected is processed as

per standards and design constants worked out.

Large dams store

very large volumes of water. Design of

such dams, therefore, has to be extra safe so that there is a minimum

probability of their failure and consequent rapid or sudden release of storage

which can cause disproportionate flooding and losses to the human habitats in

the downstream. Very stringent codes are

laid down for this purpose. In case of

inflow into a reservoir, for instance, a conceptual Probable Maximum Flood

(PMF) is determined by following special analytical procedures. If the reservoir and the spillway caters to a

properly determined outflow on the basis of such inflow, the dam

would be hydrologically safe. In similar manner, geotechnical properties of

foundation material or construction material can be determined and design

constants worked out so that structural design based on them yields a safe

structural construction. Statistically

speaking, the design constants should cover the probability of occurrence of

forces expected during the lifetime of the structure under design.

1.4 Design Philosophy

The codes of

practice invariably lag the strata or knowledge or state of Research &

Development (R&D). In fact

codification follows verification of generated knowledge and its global acceptance.

Codes, therefore, tend to remain conservative and normally incorporate a

higher factor of safety and hence perhaps yield structures with larger

dimension and/or with higher costs.

There is yet another aspect of design philosophy which is not very explicitly

understood nor adequately explained. It

pertain to the various stages of design for complex structures like dams viz.

conceptualization, pre-feasibility, feasibility, detailed project report (DPR),

pre-construction, early construction and advanced construction stages.

1.5 Refine The Design As You Build

A designer starts

with broad concept of design parameters in the beginning and goes on refining

his data base and hence the designs, as he proceeds through the various

stages. He assumes for the sake of his

inadequate data base, simplifications or generalizations which obviously

incorporates a large factor safety in initial stages. As the passes through successive stages, his

data base proves, better and more accurate data base emerges; the range of design constants narrows down

and factor of safety reduces.

Generally, the outer dimensions of a structure do not necessarily get

modified; but components, zones or internal

arrangements of a structure do undergo modification. The structure’s response to the destabilizing

forces is worked out with greater detail and is refined while moving from one

stage to the next stage. Engineers call

this a process which is loosely described as ‘Design as you build’ or ‘Refine the design as you build’ mode. It certainly does not mean inadequacy of

design or does not reflect on ignorance or incompetence of project or design

engineers. However, an inadequate

understanding of this very philosophy is one major factor responsible for much

public criticism of many of our water resources projects.

ALSO READ: FOUNDATION TREATMENT FOR DAMS

2.0 Defensive Measures

International practice recommends deployment of various

defensive measures to provide extra safety in design of high risk rockfill

dams.

- Allow ample freeboard to allow for settlement, slumping

or faul movements.

- Use wide

transition zones of material not vulnerable to cracking.

- Use chimney near

the central portion of embankment.

- Provide ample drainage zones to allow for possible flow

of water through cracks.

- Use wide core

zones of plastic materials not vulnerable to cracking.

- Use a

well-graded filter zone upstream of the core to serve as a crack stopper.

- Provide crest

details which will prevent erosion in the event of overtopping.

- Flare the

embankment core at abutment contacts.

- Locate the core

to minimize the degree of saturation of materials.

- Stabilize slopes

around the reservoir rim to prevent slides into the reservoir.

- Provide special details if danger of fault movement in

foundation exists.

This list should not by any means be considered as

all-inclusive. However, defensive

measures, specially the use of wide filters and transition zones, provide a

major contribution to earthquake-resistant design and should be the first

consideration by the prudent engineer in arriving at a solution to problems

posed by the possibility of earthquake effects.

ALSO READ: FOUNDATION TREATMENT FOR DAMS

3.0 Criteria for Safe Design of Earth/Rock fill Dam

(i) There should

lie no possibility of dam being overtopped by flood water.

(ii) The seepage

line should be well within the downstream face.

(iii) The u/s and d/s slopes should be stable under worst

condition.

(iv) The

foundation shear stresses should be under safe limits.

(v) There should

be no opportunity of free flow of water from u/s to d/s face.

(vi) The dam and

foundation should be safe against piping.

(vii) The U/s face should be properly protected against

wave action and the d/s face

against the action of rain

4.0 DESIGN OF

CORE FOR ROCK FILL DAMS

4.1 Core

4.2 The core provides impermeable barrier within the body

of the dam. Impervious soils are generally suitable for core. However, soils having high compressibility

and liquid limit are not suitable as they are prone to swelling and formation

of cracks.

Soils having organic content are also not suitable. IS:1498-1970 may be referred for suitability of soils for

core. Appendix A gives

recommendations based on

IS:14981970. Recommendations regarding

suitability of soils for construction of

core for earth dams in earthquake zones are given in Appendix B.

4.3 Core may be located either centrally or inclined

upstream. The location will depend

mainly on the availability of materials, topography of site, foundation

conditions, diversions considerations, etc.

The main advantage of a central core is that it provides higher

pressures at the contact between the core and the foundation educing the

possibility of leakage and piping. On

the other hand inclined core reduced the

pore pressures in the downstream part of the dam and thereby increases its safety. It also permits construction of downstream

casing ahead of the core. The section with

inclined core allows the use of relatively large volume of random

material on the downstream.

ALSO READ: FOUNDATION TREATMENT FOR DAMS

4.4. The following practical considerations govern the

thickness of the core:

a) Availability of suitable impervious material; b)

Resistance to piping; c) Permissible seepage through the dam; and d)

Availability of other materials for casing, filter, etc.

However, the minimum top width of the core should be 3.0 m.

4.5 The top level

of the core should be fixed at least 1 metre above the maximum water level to prevent seepage by capillary siphoning.

5.0 Casing

5.1 The function of casing is to impart stability and

protect the core. The relatively

pervious materials, which are not subject to cracking on direct exposure

to atmosphere are suitable for casing. IS:1498-1970 may be referred for suitability of soils for

casing. Appendix A gives recommendations based on IS:1498-1970.

6.0 Special Design Requirements

6.1 In addition to basic design requirements given at 5,

the following special design

requirements, should also be satisfied for both earth and rock fill

dams: a) Control of cracking. b) Stability in earthquake regions, and c)

Stability at junctions.

6.2 Control of Cracking - Cracking of impervious zone

results into a failure of an earth dam by erosion, breaching, etc. Due consideration to cracking phenomenon

shall, therefore, be given in the design of earth dam.

6.3 Reasons of Cracking - Cracking in the core of earth or rockfill dam occurs due to foundation settlement and/or differential movements within the embankment. Differential movements in the embankment take place due to the following reasons:

a) Unsuitable

and/or poorly compacted fill materials, b) Different compressibility and

stress-strain characteristics of the various fill materials, and c) Variation

in thickness of fill over irregularly shaped or steeply inclined abutments.

6.4 .Cracking also develops by tensile strains caused by

various loads, such as dead load of the structure, filling of the reservoir and

seismic forces. Hydraulic fracturing of

the core may also occur when the hydrostatic pressure at a section in the core

exceeds the total minor principal stress at that section.

6.5 Types of Cracks - Cracks may be classified based on

the following factors: a) Mechanism by

which cracks are developed, such as tensile, compressive, shrinkage or

shearing. b) Types of surface with which the cracking is associated, such as

flat or steep. c) Physical process involved, such as moisture or temperature

changes, loading or unloading action and dynamic activity, such as blasting or

earthquakes.

6.6 Tensile stresses produce cracks on flat surface by

capillary action in the moisture range

just below saturation. Tensile stress

steep slope category cracks are associated with slumping in poorly consolidated

materials.

6.7 Shrinkage

cracks are produced by wetting and drying

action in the moisture range of plasticity index.

6.8

Compression cracks on flat

surface are produced by

an abrupt change

in moisture followed by

substantial consolidation and cracking around the periphery of the affected

area.

6.9 Cracking

associated with shearing is commonly associated with steep slopes. There are two conditions in

this category. One is

differential settlement which involves

a limited range of motion and the other is a slide failure which may involve

any amount of motion. The differential

settlement condition commonly involves a structure extending over two or more

kinds of foundation with differing compressive characteristics or a

differential loading condition on a single kind of foundation material.

6.10 Slide

failures may be associated with loading ,unloading or moisture change, the distinguishing characteristics is the

potential for continued movement.

6.11 Importance

of Cracks - Relative importance of each type of crack category or group is given at 3.1.3.1 to 3.1.3.3.

6.11.1 Where permeability

and possible erosion

are of primary

concern, the tension group is potentially the most serous. In this group, the cracks are open and

although usually only superficial, those associated with steep slopes may

extend to depths comparable to the size of structure involved.

Though the development of this type of cracking is from

the surface, it may persist, although deeply buried, where eventually it may

contribute to unsatisfactory seepage action.

6.11.2 Where

maintenance of position is a prime structural requirement the compression type of cracking is the most important

because it is probable that when this type of cracking appears the settlement

has already completed.

6.11.3 Shearing

cracks are identified primarily by displacement between the two sides and a tearing configuration. Unlike tension or compression cracking,

shearing cracks commonly occur early in the failure action and further movement

can be expected after the first cracking shows up.

6.12 Measures for Control of Cracking - Following

measures are recommended for control of

cracking:

a) Use of plastic clay core and rolling the core material

at slightly more than optimum moisture content.

In case of less plastic clay, 2 to 5 percent bentonite of 200 to 300

liquid limit may be mixed to increase the plasticity. b) Use of wider core to

reduce the possibility of transverse or horizontal cracks extending through it. c) Careful selection of fill materials to

reduce the differential movement. To restrict the rockfill in lightly loaded

outer casings and to use well graded

materials in the inner casings on either side of the core. d) Wide

transition zones of properly graded filters of adequate width for handling

drainage, if cracks develop. e) Special treatment, such as preloading,

pre-saturation, removal of weak material etc., to the foundation and abutment,

if warranted. f) Delaying placement of core material in the crack region till

most of the settlement takes place. g) Arching the dam horizontally between

steep abutments. h) Flattening the downstream slope or increase slope stability

in the event of saturation from crack leakage. i) Cutting back of steep abutment

slopes.

ALSO READ: FOUNDATION TREATMENT FOR DAMS

7.0 Foundation Treatment Below Core :

The core contact area includes the foundation contact for

the entire base width of the impervious core, the upstream and the

downstream filter zones, transitions and the downstream drain. This area is the most important and critical

in the foundation treatment of earth-core rockfill dams. The controlling

factors are:

1. The rock under the core, including the infilling

material in faults and joints, must be non-erodible and must be protected from erosion under seepage

gradients that will develop under the core. 2. Materials of the core must be

prevented from moving down into the foundations. 3. The contact between the

core and the foundation rock surface must remain intact despite distortions that

might occur in the dam due to its weight and reservoir loading.

The primary hazards to a high embankment dam are cracking

within the corecaused by unequal settlement and the development of seepage

channels along the contact of the impervious core with the foundation and

abutment rock. Either of these defects could lead to failure of the dam. It must therefore be ensured that the

foundation in the core-contact area consists of sound and hard rock

reasonablyfree from joints and fissures which could be the cause of internal

erosion.

These objectives are achieved by excavation of the

uppermost weathered rock zones to the level of sound rock and by consolidation

grouting to reduce the permeability of the rock under the excavated

surface. Jointed rock is an acceptable

foundation, provided the joints do not contain soft materials or clays to an extent that could endanger the stability

of the rock.

8.0 Suitability of Soils for Construction of Earth Dam

|

Sl.No |

Suitability |

Zoned

Earthdam |

|

|

|

|

Impervious Core |

Pervious Casting

|

|

1 |

Very suitable |

GC |

SW, GW |

|

2 |

Suitable |

CL, CI |

GM |

|

3 |

Fairly suitable

|

GM, GC, SM, SC, CH |

SP, GP |

|

4 |

Poor |

ML. MI, MH |

- |

|

5 |

Not suitable |

OL, OI, OH |

- |

9.0 Suitability of Soils for Construction of Core of

Earth Dam in Earthquake Zones

|

Sl.No |

Suitability |

Type of Soil |

|

1 |

Very Good |

Very well graded coarse mixtures of sand, gravel and fines., D85 coarser than 50mm, D50

coarser than 6 mm. If fines are cohesionless,

not more than 20 percent finer than 75 micron IS Sieve. |

|

2 |

Good |

a) Well graded mixture of sand, gravel and clayey fines, D85 coarser than 25 mm Fines consisting of inorganic clay (CL with plasticity

index greater than 12). b) Highly plastic tough clay (CH with plasticity index greater than 20). |

|

3 |

Fair |

Fair a) Fairly

well graded, gravelly, medium to coarse

sand with cohesionless fines, D85

coarser than 19 mm, D50 between 0.5 mm and 3.0 mm. Not more than 25

percent finer than 75 micron IS sieve. b) Clay of medium plasticity (CL with

plasticity index greater than 12). |

|

4 |

Poor |

) Clay of low plasticity (CL and CL-ML) with

little coarse fraction.

Plasticity index between 5 and 8.

Liquid limit greater than 25. Liquid limit greater than 25. b) Silts of medium to high plasticity (ML or MH) with little coarse fraction. Plasticity index greater than 10. c) Medium sand

with cohesion less fines. |

|

5 |

Very Poor |

a) Fine, uniform, cohesion less silty sand, D85 finer than 0.3 mm. b) Silt from medium plasticity to cohesionless

(ML) Plasticity index less

than 10. |

10.0 Location of Core in Dam Section and Type of Core

The core can be

located in one of the following three positions:

(1) central,

(2) moderately

slanting or

(3) slanting.

The central location need not be exactly symmetrical: cores with a steeper downstream

slope and flatter upstream slope, or

even with a slight slant in the

upstream direction would still have

characteristics of central cores.

When the downstream face of the core has an upstream

slant of 0.5 H : 1 V or more, the core

may be considered as moderately slanting.

A truly slanting

core would be such that the downstream zone has a self-supporting slope, i.e., 1.25 H:1 V or more,; such a core is

almost always associated with a rockfill

dam in which the main mass of rockfill downstream of the core can be

placed independently by dumping or in thick layers and the placement of filter

zones, core and upstream pervious zone

taken up later. Even with a moderately slanting core, if the downstream rockfill zone is

substantial, it is possible to carry out a

portion of the work ahead of core

placement.

The relative advantages and disadvantages of vertical and

sloping cores are discussed below:

ALSO READ: FOUNDATION TREATMENT FOR DAMS

10.1 Slanting Core

Advantages

j) Downstream rockfill can be placed in advance and

laying of filter, core and upstream zone

can be taken up later. This ensures

rapid progress as placement of bulk

rockfill in the downstream portion is accelerated, especially in

conditions wherein core placement is

possible only during part of the year.

ii) Foundation grouting of the core can be carried out

while the downstream shell is being placed and thus better progress achieved.

iii) Since a very small part of the slip surface

intersects the slanting core, the section is practically free from the steady

seepage pore pressures and is thus

more stable under a steady-state condition. This results in a steeper slope of the

downstream shell and corresponding economy.

iv) Since the flow lines are essentially vertical and

equipotential lines are almost horizontal under sudden drawdown, the drawdown

pore pressures are very much reduced.

However, a larger part of the slip surface for the upstream slope passes

through the core material than would be the case with a central core.

v) In the case of cracking of the core, the inclined core

will leave a large mass of stable rockfill on the downstream side and is likely

to be safer. vi) Filter layers can be made thinner and placed more

conveniently.

Disadvantages

i) The depth of excavation of the foundation at the

contact surface of the core is determined by the nature of the formations and

cannot be predetermined in advance. Thus

advance treatment of the contact area may present a problem in the case of a

slanting core because if the depth of excavation increases, the contact area

moves upstream.

ii) By slanting the core upstream, although the

downstream slope can be made steeper, nevertheless, the upstream slope will

generally become flatter as the shear strength of the core material will be

less than that of the pervious shell material; the advantage of reduced

drawdown pore pressures may not compensate this factor. Thus any economy in total quantity of materials

by adjustment of core position would depend on the relative strength of the two

materials.

10.2 Central Core

Advantages

i) Provides higher

pressure on the contact surface between the core and the foundation, thus reducing the possibility

of hydraulic fracturing.

ii) For a given quantity of soil, the central core

provides slightly greater thickness.

iii) Provides better facility for grouting of foundation

or contact zone or any cracks in the core if required afterwards, as this can

be done through vertical rather than inclined holes.

iv) Foundation area is independent of depth of foundation

and hence can be marked and treated in advance.

Disadvantages

i) The advantages

listed for a slanting are not obtainable.

Also, a moderately thick central

core with pervious shells will result in a slightly flatter downstream slope of the dam. ii) The problem of differential settlement

between the core and the shell zone

may result in cracking parallel to the dam axis.

11.0 Design of Filters for Earth/Rockfill Dams

11.1 Introduction

Water conservation

and development of water resources for irrigation have attracted human

ingenuity since time immemorial. A

number of ancient tanks and earthen embankments stand testimony to the skill of

our ancestors. The Grand Anicut across

Cauvery River, built more than 1600 years ago and providing irrigation to 0.4

million hectares of land, is a typical example of the ancient earth dams in the

country, still in service today. In the

past, design of earthen dams was mainly carried by the rule of thumb and

judgment of the designer, and the heights adopted were moderate. Advances in the field of soils mechanics and

construction equipment over the years have made it possible to design and

construct earth/rockfill dams to heights which would have been considered

impossible in the past

Design and

construction practice for embankment dams have undergone a number of changes

over the years. One of the important

features that could be noticed is recognition of the useful role of ‘protective

filters’. Analysis of the performance of

embankment dams in the world showed that there are almost no cases of damage or

failure by piping, when filters had been provided as per accepted design

practices, and most of the failures had

occurred in dams without chimney filter or which had excessively coarse

filters. Well planned filter drainage

has become obligatory in the design of modern dams. Filters are provided to safely carry the seepage

water which may pass through the body of dam, through the foundations, or along

their contact, thus protecting the structure against the undesirable and

harmful effects of seepage. Generally

seepage is expected to occur through the pores of the base soil. But there could be a more severe condition of

water leaking through cracks which may develop in the dam body foundation

system. Enough evidence already exists

from the observed behaviour of dams, supported

by theoretical calculations, that such concentrated leaks can develop

due to various reasons. Fortunately,

recent studies have shown that the filters, if adequately designed can also be

effective in controlling erosion through

such concentrated leaks. The embankment

dam designer should therefore pay adequate attention in arriving at a proper

design of these filters.

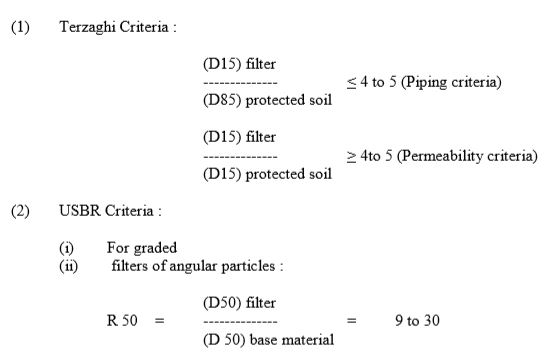

The filter criteria contained in the IS code is based on

the criteria recommended by Terzaghi and studies carried out with non-cohesive

soils. There is scope to improve the

provisions in the code to cater all soil types.

Recent studies, which included controlled laboratory tests performed by

various agencies and individuals ha e brought out some new findings on the

evolution of criteria for conservative/critical filters, capable of preventing

erosion and sealing off concentrated leaks.

Particulars of this modified criteria and details of its adoption in

rehabilitating a dam are briefly described.

Some other situations where protective filters could be advantageously

used, are also discussed.

12.0 Conservative Filter Criteria

As per the Indian Standard Code (IS: 9429-1980) a

properly designed filter should satisfy the following requirements:

ALSO READ: FOUNDATION TREATMENT FOR DAMS

a) It should be much more pervious than the protected

base material. b) It should be of such gradation that particles of the base

material do not migrate through or clog the filter voids. c) It should be

sufficiently thick to provide a good distribution of all particle sizes

throughout the filter.

13.0 Other

criteria for design of filter are as follows:

The above criteria takes into account only the grain size

of base material, and is based on

studies made with non-cohesive soils.

Even though the filters are provided generally to take

care of the seepage through the pores of

the embankment soils, they should

also be capable of preventing erosion of

soils through concentrated leaks that may occur in the dam body or at the

foundation contact.

Certain improvements and modifications to the above

criteria have been brought recently on the basis of controlled laboratory tests

performed by various organizations and individuals. Contributions by the US

Department of Agriculture, Soil Conservation Service is worth making a special

mention. Filter tests have been

conducted using compacted impervious soil specimens with an artificial slot or

hole and subjected o water flow discharging into the filters of varying coarseness. These studies confirmed that a conservative

filter would be remarkably effective in preventing erosion and sealing off

concentrated leaks, even with relatively high water pressures, velocities and

gradients. Such filters are required on

the downstream face of impervious core of a zoned embankment dam, and in the

chimney filter of a homogeneous dam section.

Because of the important role of these filters they are also known as

‘critical filters’. Some of the useful

conclusions drawn from the studies are :

i) The gradation curve of a filter need not have to be

parallel or similar in shape to the gradation curve of the base material.

ii) A filter should be uniformly graded to provide

permeability and prevent segregation.

Particles finer than 0.075 mm in the filter should not exceed 5 per cent

to ensure adequate permeability. The

permeability of a filter should be at least 25 times that of the base material

(D15F should be more than 5xD15B).

iii) Coarse broadly graded soils need finer filters than

believed to be necessary. The filter

should be designed to protect the fine matrix of the base material

rather than the total range of particle sizes. Filters designed based on minus 4.75mm are

found to be satisfactory.

iv) Sands and gravelly sands with average D15 size of 0.5

mm or smaller are conservative filters for most of the fine-grained clays

(including dispersive clays) in nature with D85 size of 0.03 mm or larger.

v) Sand filters with average D15 size of 0.1 mm or

smaller are conservative for the finest dispersive clays. Based on the above

findings, the US Interior Bureau of Reclamation (USBR) has developed a new set

of filter criteria (2). The filter

gradation limits are determined through steps A to B as described below:

A. Select the gradation curve of the base soil that requires

the smallest D15F size.

B. Proceed to step

D if the base soil does not contain gravel (4.75 mm and above).

C. Prepare adjusted gradation curves for soils with

particles larger than 4.75 mm. Use the

adjusted curve in working step D.

D. Determine the category of the soil from Table-1.

E. Determine the maximum D15F size in accordance with

Table-2.

F. To ensure sufficient permeability set the minimum D15F

size greater than or equal to 5xD15B, but not less than 0.1 mm.

G. Set the maximum particle size at 75 mm and the maximum

passing 0.074 mm must have a plasticity index of zero.

H. Design the filter limits within the maximum and

minimum values determined in steps E, F and G.

Plot the limit values and connect all the maximum and minimum points by straight

lines.

Typical filter gradation limits arrived for a category 2

type of base soil

ALSO READ: DESIGN PRINCIPLES OF EARTH DAM

No comments:

Post a Comment